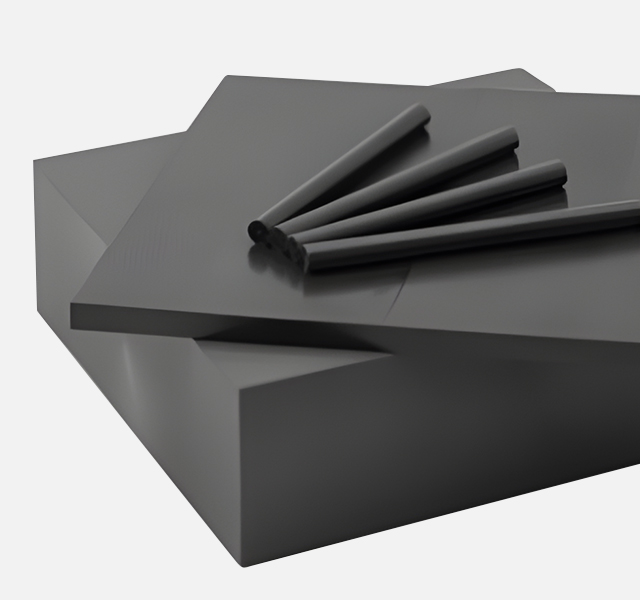

Zenimid™ PI Natural Grade

Features

- Semi-finished products such as Sheet

- Mainly Used for machining customized products

Application

- Roller, Guide Pin, Vacuum Pad, etc.

PI Advanced Materials enable the possibility of Polyimide with creative innovation.

It connects people, society, and the world.

Powered by PI Advanced Materials’ best-in-class R&D and manufacturing capabilities, our PI varnish and powder/mold materials offer tailored solutions to a diverse range of industries and customers

Total Solution Provider

of PI power/mold materials

Display Business

Certification and supply of process components for major display customers

Semiconductor

Business

Provide material solutions that meet the levels of etching resistance and chemical resistance required in the semiconductor process

New Businesses

(Automotive, Aerospace, etc.)

Promoting portfolio diversification in high-performance engineering plastics fields such as EV and aerospace

Display

PI Advanced Materials' Zenimid™ polyimide mold is a material solution that satisfies the high heat resistance, wear resistance, and low friction coefficient required in display etching, deposition, and heat treatment processes, and is applied to various components of major display companies.

Semiconductor

It is used as a core material for semiconductor front-end and back-end process components that require high etching resistance, chemical resistance, and dimensional stability, such as etch rings, vacuum pads, and test sockets.

New Business

Zenimid™ Polyimide Mold is a super engineering plastic material with the highest level of physical properties among engineering plastic materials. It is being applied to various fields in line with the needs of electric vehicles (EV), aerospace, and defense equipment, which require light weighting and at the same time high levels of physical properties such as wear resistance, insulation, and heat resistance.

Built on proprietary technology, PI Advanced Materials’ Zenimid™ has a broad range of applications from machinery and display to semiconductors and aerospace industries. Zenimid™ is a new solution for industrial applications requiring reliable performance under the most severe operating conditions.

Zenimid™ can maintain its original properties even at 300℃ and dimensional stability upto 500℃.

Self-lubricating and highly heat resistant, Zenimid™ can retain its original shape and size against high friction and abrasion.

Zenimid™s excellent elasticity allows high-precision processing of small tolerance components.

Zenimid™’s ability to retain its original dimensions under high-pressure and temperatures makes it ideal for component integration applications.

If you wish to make an inquiry regarding a product, please contact our representatives below.